|

|

|

|

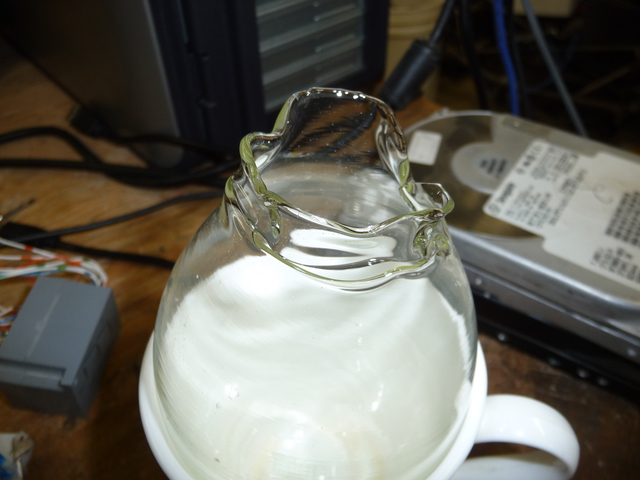

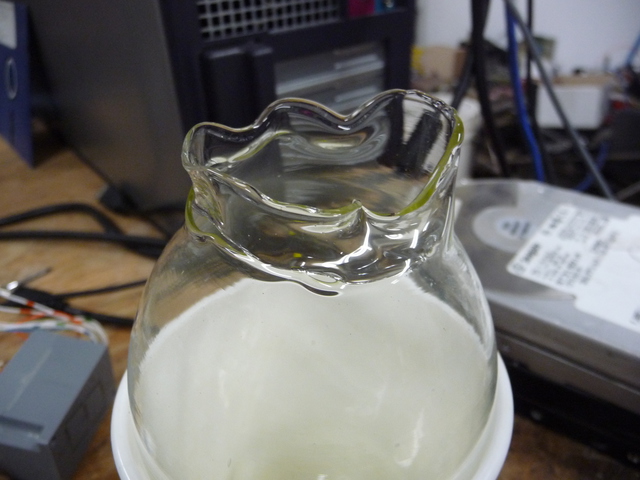

Oh come on, a used solder pot is like $20.00 on ebay. Tomorrow on lifehacker, how to store gasoline in lightbulbs!

and so, here we go!

|

|

|

|

|

|

|

|

|||||||||

|

How (not) to store gasoline in a lightbulb. Do not do this at home.

|

|

|||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

fartface says: