Servos have a 3 pin connector,

consisting of ground, supply voltage, and control signal. Pinouts have

been known to vary by manufacturer.

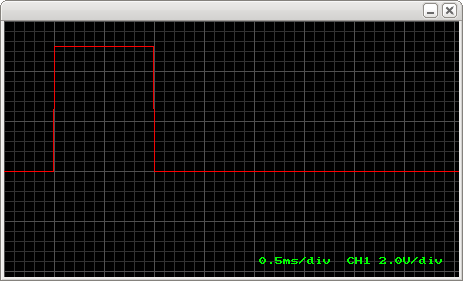

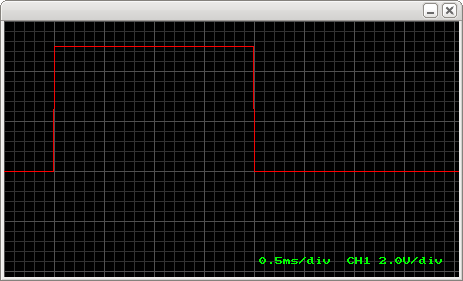

Servos are controlled by sending it a

variable width pulse (a type of Pulse Width Modulation (PWM)).

Important paramiters about the shape of the pulse are the 'centre

duration' and repetition rate. A servo often turns less than 180

degrees on the output shaft over the rated minimum and maximum output

pulse lengths.

The centre position of the servo is defined by a pulse width input of

1.5ms high (it should be the shaft position in the middle of its

capable movement). The standard pulse width range is 1ms to 2ms, which

is often described as having a 180 degree difference in the output

shaft, but often does not. (you can go wider on the pulse width

changes, for example .9ms to 2.1ms which, depending on the servo, may

give you more movement.)

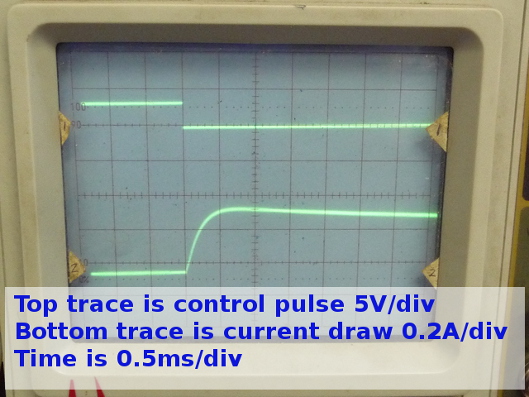

Every time a control pulse is sent to a non-digtital servo, it performs

a position 'correction'. The designed correction rate (pulse rate) is

50Hz, or a new pulse every 20ms, more about that later.

So, in summary, the servo expects to see a pulse every 20 milliseconds

(ms) and the length of the pulse will determine the output position.

For example:

- 1.5ms pulse will make the motor turn to the 90-degree

position.

- 1 ms pulse moves it to 0 degrees

- 2 ms pulse will turn the servo to 180 degrees

Its good to know HOW the servo controls

its position, if you know this you can pull some interesting tricks,

like adjusting the gain and force feedback.

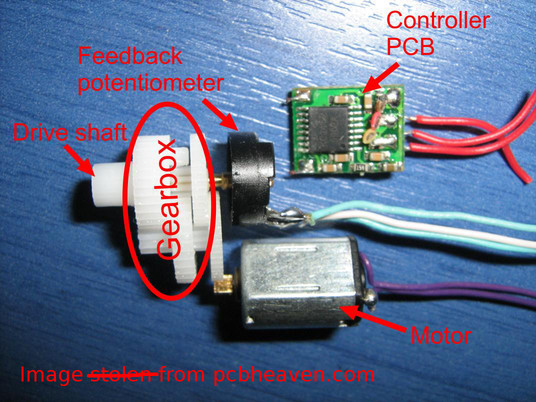

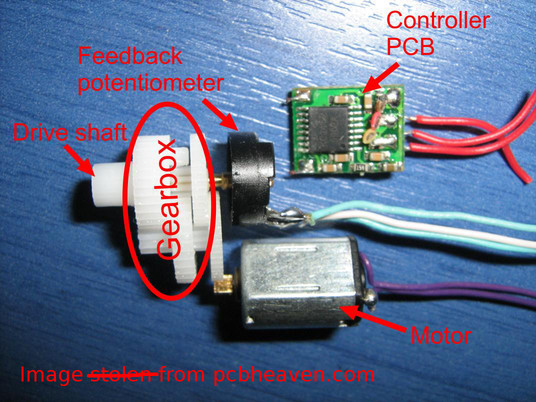

Inside a servo is a:

Motor

gearbox

potentiometer

control circuit

The motor is attached by gears to the output shaft, which is

attached to the potentiometer. As the motor rotates, the

potentiometer's resistance changes, so the control circuit can read the

output position to make any needed corrections.

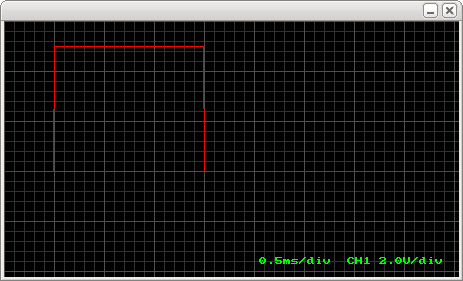

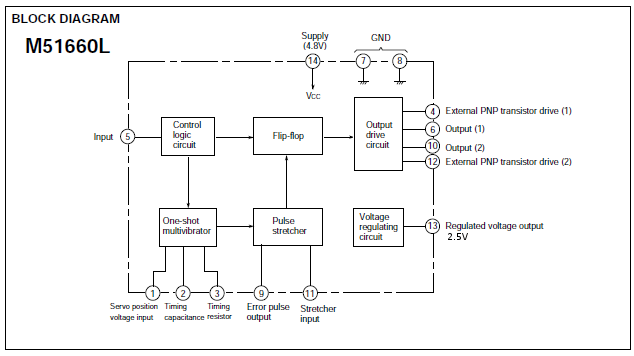

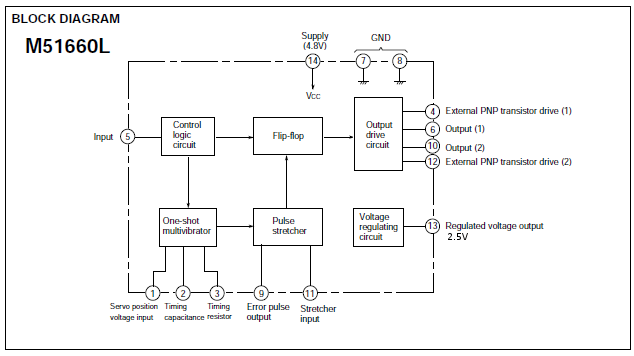

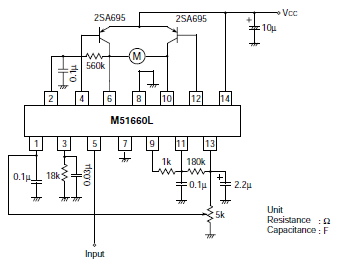

As already stated, the control signal is a pulse between 1 and 2ms long.

The internal potentiometer is attached to a circuit that also generates

a pulse between 1 and 2ms, but the length is determined by the position

of the output shaft.

This internal pulse is triggered by the start of the control pulse.

The circuits goal is to make the two pulse lengths match, this means

the servos position matches the 'joystick position'.

These two pulses are compared, to generate a 'difference pulse'.

Direction of the correction can be determined from the timing of the

difference pulse:

- If the difference pulse occurs while the control pulse is still high,

this will mean the motor has to turn, say, counterclockwise.

- If the difference pulse occurs when the control pulse is low (as in

after the control pulse finished), it would mean the motor has to turn,

say, clockwise.

The length of the difference pulse determines how much power the motor

needs to get. This gets more creative.

This is where the term 'Proportionate' (the same P as in PID) comes

from, the pulse is proportionate to the error.

What they do, is use whats called a 'pulse stretcher', this multiplies

the length of the difference ("error") pulse.

This multiplied pulse (it can be up to 17ms long. We have 20ms between

control pulses, if the control pulse is 1ms and the internal pulse is

2ms (worst case error) we have 17ms left to fix position till the next

control pulse comes along. In actuality the multiplied pulses are never

this long.) is sent directly to the motors driver circuit.

If there is no error, the motor doesn't recieve a pulse.

If there is a large error, the motor will be sent a longer pulse,

effectivly recieving more power. (PWM, the duty being the multiplied

pulse, the rate being the freq of the incomming control pulses)

It's important to note that the servo may not completely correct the

position difference within one pulse, it just makes 'progress'. This is

why its important to keep repeating the pulses to the servo.

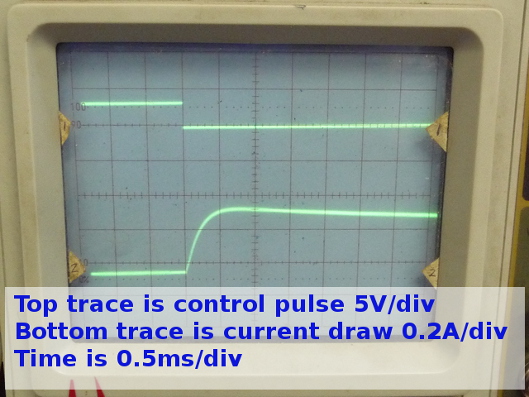

As you can see, the motor will recieve correction power if the control

signal changes OR if the shaft position changes. This allows the servo

to hold its position like it does. Which is also why you get

'twitching' on a heavily loaded servo where the load on it can move it

back a little between pulses. (this is not related to the twitching

caused by avrlib which is a code timing issue)

A loaded servo, will never be able to completely correct the error, so

the motor will be recieving correction pulses every time there is a

control pulse, and the motor will draw current for that period, which

is proportional to the load on it.

Did you read into this enough to learn how to adjust the average power used to correct the motors position?

Other stuff you wont find much anywhere else:

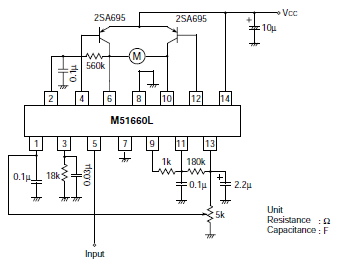

Joystick 6 channel multiplexor:

Servo 6 channel demultiplexor:

Who can tell how to expand this to 9 channels?

Who can tell how to use this to expand 1 pin of a microcontroller to operate 9 servos?

Well they thow out all the 1960's

technology in the previous paragraph and drop in a microcontroller, the

microcontroller measures the length of the incomming pulse, memorizes

it. It continiously reads the potentiometer and uses the difference in

readings to control a higher frequency pwm stream to the motor driver.

(welcome

to 1970's tech }:] ) This means that it can make corrections

without having a stream of control pulses. This allows it to get closer

to the target position between the control pulses. To my knowledge most

of these will go into 'shutdown' mode if it dosn't recieve control

pulses over a timeout period, but I'v never been able to afford the

goofy things, I usually can't afford standard servos, so I take a big

gearmotor, position detector, motor driver, and microcontroller and

make my own.