|

|

|

|

|

|

|

|

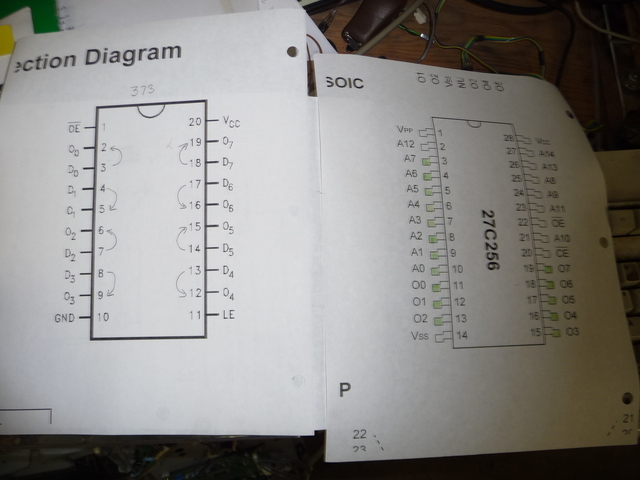

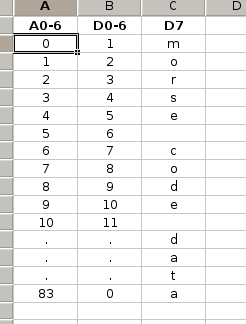

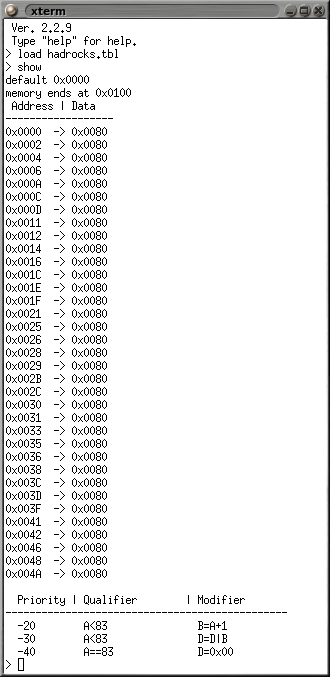

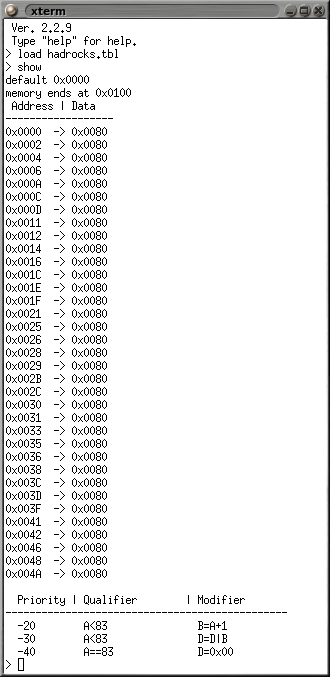

> We need software! I wrote, back in 2009, a program for generating table or equation based memory images. This allows me to take a mix of

equations and defined content and build an ihex file. Designing the memory for this isn't hard, there are two parts, one is that D0-D6 need to contain

the address of the next memory location, part two is that D7 needs to have the morse code data. Because the memory cells default to 0, I only need to

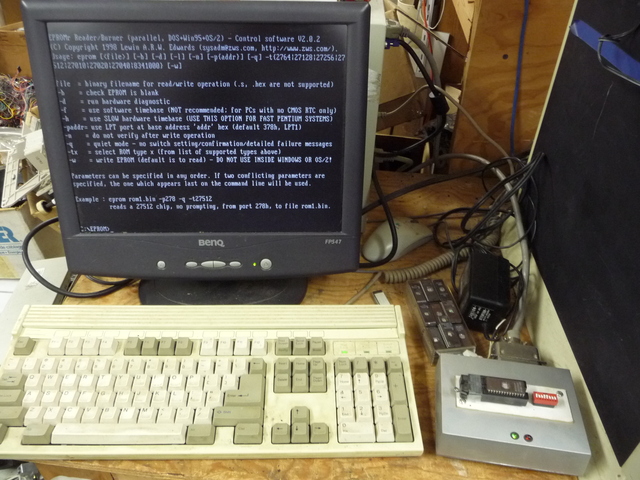

specify the 1's for the morse code. My program works via command prompt, I'm showing you the program for the memory chip without going into gorry details

on how to get there. The program outputs a .ihex file, My eprom software can only take binary images, so I use ihex2bin to convert the results.

oops, I wrote that too, contact me if you want a copy...

My program is free to those interested, I dont have it posted, if you want a copy ask, I should clean it up just a bit before

handing it out. For those interested, Modifiers are only run if Qualifier isn't 0, A is the current address, D is the data for that memory location

rules are applied against each memory address from highest to lowest, positive rules before literals and negitive rules after literals. |

|

|

|

|

|

|

|